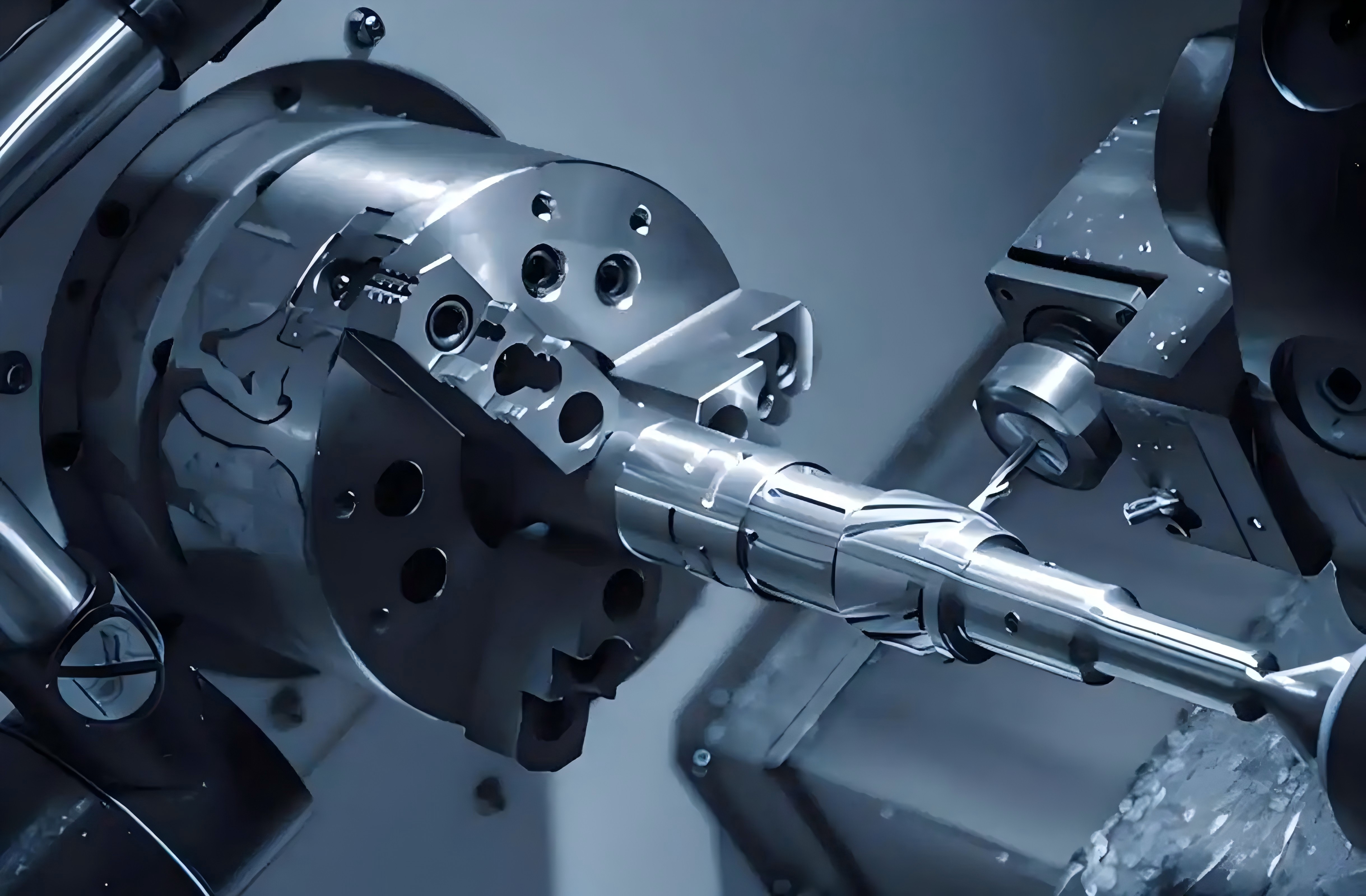

China Business Intelligence Network reports: High-end CNC (Computer Numerical Control) machine tools refer to numerically controlled machine tools capable of achieving high-precision, high-complexity, high-efficiency, and high-dynamic processing. Since the start of this year, driven by emerging industries such as humanoid robots and new energy vehicles, orders for machine tool enterprises have surged, with particularly strong demand for mid-to-high-end CNC machine tools.I. Analysis of the High-End CNC Machine Tool Industrial Chain The high-end CNC machine tool industrial chain can be divided into three segments:upstream, midstream, and downstream.Upstream of the industrial chain: Components and systems.Precision materials include high-end alloy steel and carbon fiber.Components cover spindles, intelligent sensors, ball screws, and guide rails.Systems consist of numerical control systems and servo systems.Midstream of the industrial chain: Complete machine manufacturing of high-end CNC

More

China Business Intelligence Network reports: High-end CNC (Computer Numerical Control) machine tools refer to numerically controlled machine tools capable of achieving high-precision, high-complexity, high-efficiency, and high-dynamic processing. Since the start of this year, driven by emerging industries such as humanoid robots and new energy vehicles, orders for machine tool enterprises have surged, with particularly strong demand for mid-to-high-end CNC machine tools.I. Analysis of the High-End CNC Machine Tool Industrial Chain The high-end CNC machine tool industrial chain can be divided into three segments:upstream, midstream, and downstream.Upstream of the industrial chain: Components and systems.Precision materials include high-end alloy steel and carbon fiber.Components cover spindles, intelligent sensors, ball screws, and guide rails.Systems consist of numerical control systems and servo systems.Midstream of the industrial chain: Complete machine manufacturing of high-end CNC

2025-11-11

2025-11-11

1

1

Shortly after the 2025 Spring Festival, Lao Zheng stared blankly at the "old companion"—a machine tool that had been in use in his factory for seven or eight years. "The factory next door introduced new machine tool equipment and a fully automated production line not long ago, and snatched away many customers. Of course, I’m tempted too. But when I look at the cash flow in the accounts, it can probably only support the factory for another half a year at most," he sighed.This scene may be a microcosm of the current state of most machine tool enterprises. During the window period of industry reshuffling, should they choose to stay conservative for stability or pursue innovation for breakthroughs? Can conservatism really guarantee stability? And where can they find the courage and capital for technological iteration?Corresponding to the personal struggles of those deeply involved in the industry, the 2024 statistical data of the machine tool industry is like a mirror, reflecting both the

2025-11-11

2025-11-11

1

1

Machine tools, as the "mother machines" of industry, are the foundation and core equipment of manufacturing. Their development level is directly related to a country's industrial strength. In recent years, as China's manufacturing industry has transformed towards high-quality development, the machine tool industry has also undergone profound changes. This article will comprehensively analyze the current market situation, policy environment, competitive landscape, and future trends of China's machine tool industry in 2025, revealing the industrial logic behind the increase in the numerical control rate to 51%, as well as how domestic machine tool enterprises can break through in the waves of high-end and intelligent development. I. Analysis of the Current Situation and Market Size of China's Machine Tool IndustryAfter years of development, China's machine tool industry has established a complete industrial system and has become the world's largest producer and co

2025-11-11

2025-11-11

1

1

I. Overview of precision metal parts industry Precision metal parts refer to the use of high-precision equipment, metal processing technology, digital assembly, automation technology, etc. to process metal materials into metal parts of customized shapes or sizes. Compared with general industrial products, precision metal parts not only have the characteristics of metal parts such as strong product stability, good fatigue resistance and anti-attenuation performance, but also have the precise characteristics of strong professionalism, high processing accuracy and good surface finish. Precision metal parts usually assume certain functions in instruments and equipment, such as connection, contact, support, fastening, shielding, heat dissipation, protection, etc., and are widely used in machine tools, automobiles, communications, computers and other industries.II. Development background of precision metal parts industry In recent years, the issuance and implementation of many policies and

2025-11-05

2025-11-05

1

1

1. Industry background and development statusPrecision parts manufacturing refers to the comprehensive use of high-precision metal forming technology, precision testing, computer technology and other modern technologies to process metal or non-metallic materials into predetermined shapes and sizes through pressure casting, molten mold casting, extrusion casting, model forging, stamping, cutting, powder metallurgy and other forming methods. The process of parts.Compared with ordinary parts, precision parts have the characteristics of high processing accuracy, small dimensional tolerance and high surface finish. They can be widely used in analytical instruments, oil and gas services, semiconductor equipment, medical equipment, air transportation and other fields with high requirements for equipment precision and quality. The precision parts manufacturing industry is a cross-industry of the material processing industry and the machinery industry, which originated in economically developed

2025-11-05

2025-11-05

1

1

China's high-end equipment manufacturing industry has become a pillar of the global market. According to the "2025-2030 China High-End Equipment Manufacturing Industry Market Research and Investment Potential Analysis Report" by CRI, it is predicted that the scale of China's high-end equipment manufacturing market will exceed 20 trillion yuan in 2025, accounting for more than 35% of the global market share. In the sub-sectors, intelligent manufacturing equipment, new energy equipment, and high-end CNC machine tools have seen significant growth.

2025-06-17

2025-06-17

1

1