Time:2024-07-21 Preview:1

This article is reproduced from [People's Daily Online];

With an investment of more than 5 million yuan, production efficiency increased by 25%

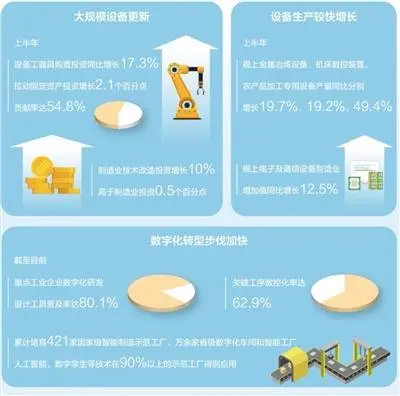

The workshop is equipped with new equipment (mid-year economic micro-observation)

Data source: National Bureau of Statistics, etc.

The picture shows the newly built special processing workshop for drilling, tapping, cutting and milling.

Photo by Liang Xiaoju (People's Vision)

With an investment of more than 5 million yuan, production efficiency has increased by 25%. Gu Xiaolin, head of Chaoyu Machinery Co., Ltd. in Yongming Town, Santai County, Mianyang, Sichuan, thinks the digital transformation is worth it.

Every 1 second, the pneumatic CNC punch presses once, and on the fourth time, an end plate with a uniform number of holes can be formed. In the workshop, operator Huang Xiaoli neatly picks finished products in front of the machine tool.

"After the equipment is updated, it is much less troublesome." Gu Xiaolin said.

Gu Xiaolin began to think about digital transformation in 2016. "The market competition is fierce. If you want to survive, you must transform." After visiting a smart spinning factory in an eastern province, this idea became stronger.

The transformation process is full of challenges. The technicians hired from other places at high salaries did not have enough understanding of the company's products, and they only cared about the beginning and not the end when renovating the equipment; they invested money to upgrade the production line, but could not produce in batches, and more than 200,000 yuan was wasted... "Some experts suggested integrating equipment, and the production efficiency of a single product was improved, but we have more than 100 other products. Some advocated mechanical linkage. In case of subsequent equipment failure, the entire production line would have to stop." Gu Xiaolin said.

Realizing that he could not be a "hands-off shopkeeper", Gu Xiaolin began to calculate carefully. With the foundation of physics, he studied the production line in depth, combined with the needs of the company, and looked for areas for improvement. "The first thing is to change the equipment! It's not a new one, but adding new functions to the old machine, adding sensors to the equipment, and integrating the mold into one, so as to save costs." In Gu Xiaolin's view, small and medium-sized enterprises have limited funds, and digital transformation requires money to be spent on the cutting edge.

The investment is not large, but the 8 pneumatic CNC punching machines after the transformation can integrate traditional production processes. "In the past, the machine only moved when I stepped on it. Now it is fully automatic, with high production efficiency, and we are relieved." Huang Xiaoli said.

On one side of the workshop, material unloading, drilling and cutting are done in one go. Under the operation of 4 red robotic arms, air conditioner spare parts are produced in batches. Compared with the old robotic arms, this set of new equipment, which was put into use in March this year, can operate the machine tools with two arms synchronously.

Lack of people and technology are the biggest "stumbling blocks" in the transformation. "Thanks to the help of the government and the coordination of the enterprise assistance specialist, the problem was solved." Gu Xiaolin said.

In order to promote enterprises to better realize "smart transformation and digital transformation", Yongming Town organized a team of experts to visit and guide "one-on-one". A contact list of town-level leaders of 13 key enterprises in the jurisdiction was established to provide full policy support. Wang Jing, deputy chairman of the Yongming Town People's Congress, was specifically connected to Chaoyu Machinery.

After hearing about the difficulties of the enterprise, Wang Jing and the commissioner of the Santai County Industry and Information Technology Bureau rushed to the enterprise. There were problems when installing the collaborative robotic arm, which was prone to collision risks. Wang Jing and the commissioner asked programmers to help. After the equipment was debugged, the efficiency doubled. If the smart equipment fails and the factory lacks maintenance personnel, the specialist will help connect with the smart equipment maintenance team and provide solutions.

On July 1, the enterprise Internet of Things system was launched. Open the phone, tap the software, and the raw materials, inventory, output and other information are clear at a glance. "Every employee, every device, and how many products are produced every day are all clear." Pointing to the equipment status information on the phone, Gu Xiaolin said.

In the past, paper list data was not updated in time, and manual statistics were inevitably missed. Today, the Internet of Things system automatically captures equipment data and accurately controls product quality, becoming the "central nervous system" of the entire production process. After the equipment is tested, it will alarm for unqualified products, and the manual will immediately find the cause and feedback the problem to the background as soon as possible, greatly improving the product qualification rate.

For the Internet of Things to run stably, the network communication problem of the computer room must be solved. Under the coordination of Wang Jing, the interface network dedicated line that originally took half a month to set up was solved in just one week.

Today, digital equipment can be seen everywhere in the workshop of Chaoyu Machinery. After the digital transformation, the company's product energy consumption was reduced by 30%, costs were saved by 35%, and the product qualification rate was increased to 98%.

A while ago, Gu Xiaolin received good news from the Mianyang Economic and Information Bureau: the company's "Digital Construction of Intelligent Production Lines for Fine Metal Products Manufacturing" project was included in the Mianyang City 2023 Enterprise Digital Transformation Typical Cases. "There will be a bonus of 500,000 yuan! Before October, we plan to invest in the transformation of 30 more mechanical equipment to continue to improve production efficiency, and this money will come in handy." Gu Xiaolin is full of expectations.